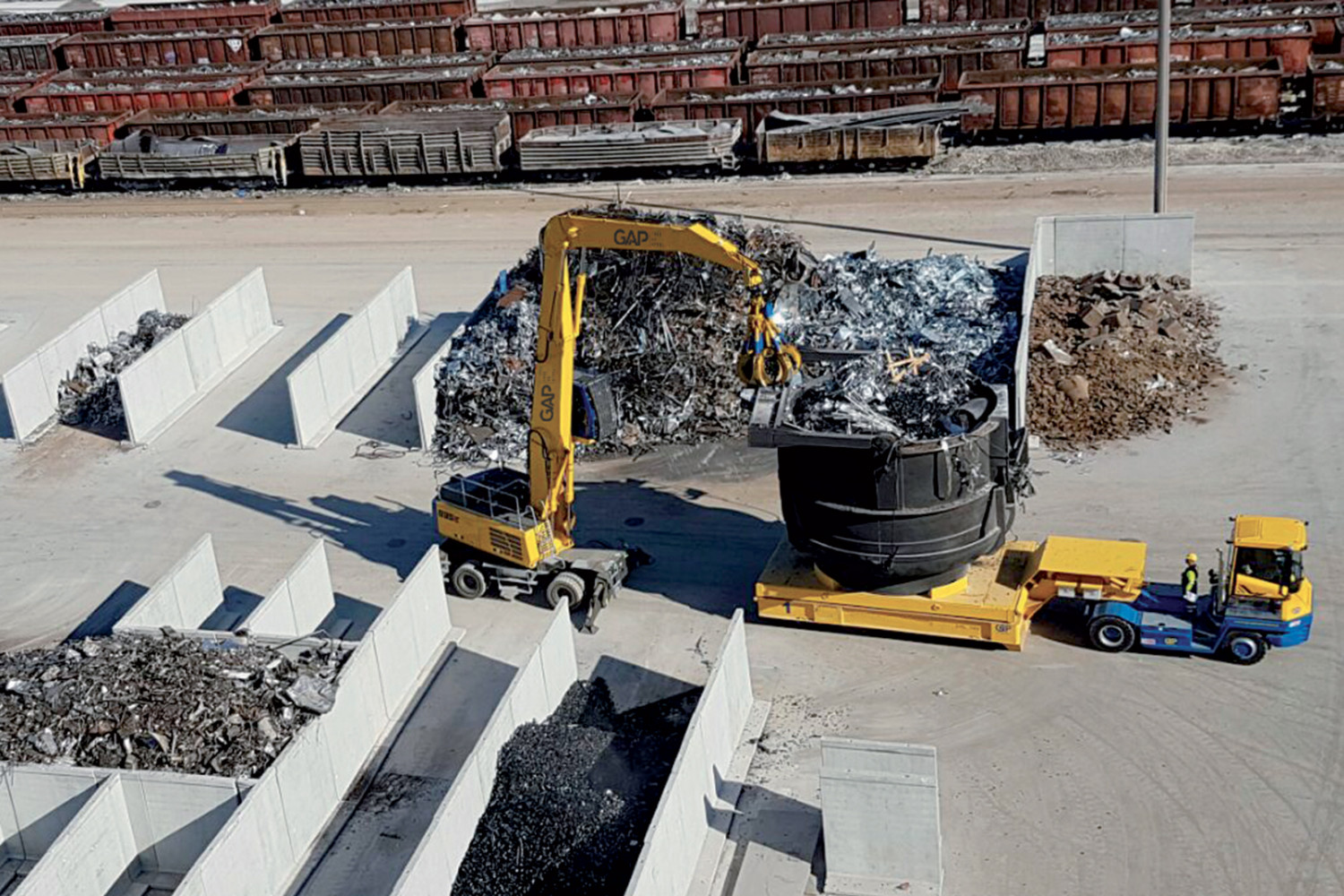

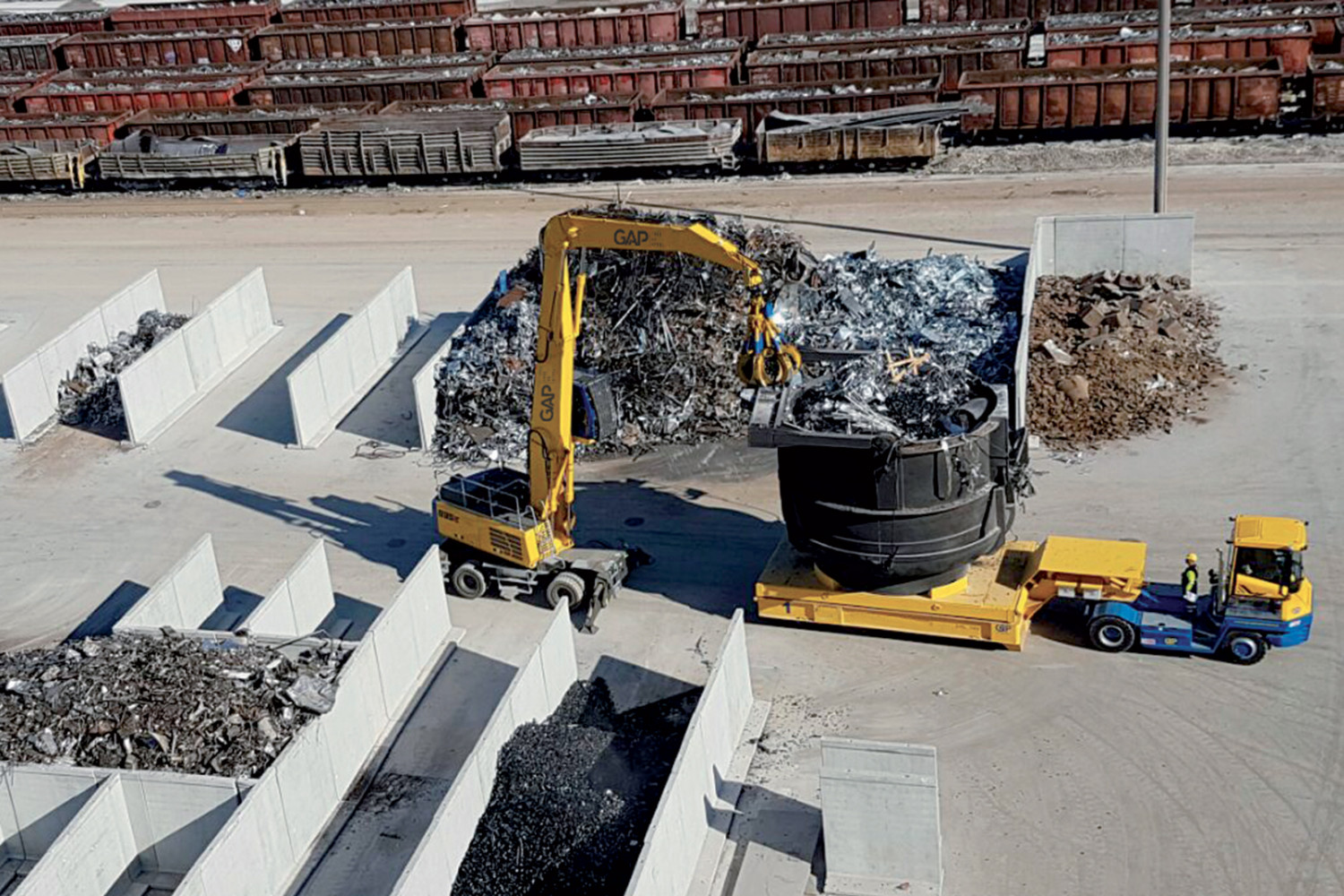

We take care of the reception, selection and stacking of ferrous scrap material by managing and coordinating the unloading of incoming lorries and trucks with the help of industrial loaders and overhead cranes; we also deal with the separation and stacking of the scrap material, based on the needs of the single steelworks..

Scrap material is usually stored in piles and loaded into special containers such as baskets, cargo beds and hoppers, in strict compliance with the technical specifications received, and then sent to the EAF (Electric Arc Furnace) for melting.

Each operation linked to the loading and unloading phases of the scrap metal and the logistics of the steel plant is constantly monitored using special software and data analysis systems.

70 years of experience gained in the field and the fine-tuning of innovative industrial vehicles allow us to create entire “turnkey” scrap yards (from unloading the incoming scrap to delivery to the furnace), managed by dedicated software, which can provide a detailed analysis of all the information needed by the customer: casting output, analysis management of castings, physical storage management, scheduling, cost analysis.